Preventing Road Rash

Lazyrolling armored reflective jacket (e-RIDES version)

Overview

Asphalt is great for tires but it’s not great for skin. The road rash that results from sliding across asphalt can range from minor scrapes to burns that require skin grafts. To prevent it, wear abrasion resistant materials over areas that are likely to slide on the road.

At slower speeds, skate pads provide pretty good protection. At higher speeds, as the risks of road rash increase, I recommend switching to either a hard shell armor jacket or a motorcycle street jacket.

Personally I prefer street jackets because they’re specifically designed and certified for street use, though some of the better armor jackets probably provide comparable protection.

| Protection type | Speed range (mph) | Standard |

|---|---|---|

| Skate pads | <20? | EN 14120 |

| Hard shell body armor | <40? | (none) |

| Urban-rated motorcycle clothing | <40 | EN 17092 class A |

| Touring-rated motorcycle clothing | <75 | EN 17092 class AA |

Many sellers of cheap gear on sites like Amazon and AliExpress lie about the material of their motorcycle garments, claiming to use expensive abrasion resistant materials. On these sites, I suspect that many “Cordura” jackets are actually polyester, and many “leather” jackets are synthetic leather, aka pleather. It’s not clear that they provide more protection than a regular jacket.

Skate pads

The European roller sports standard, EN 14120, tests pads for both abrasion resistance and impact protection. Pads certified as CE level 1 must withstand a 16 meter slide against an abrasive belt without wearing through, while CE level 2 pads are subjected to a 64 meter slide.

EN 14120 also tests pads to ensure they stay in place when impacted. Overall, these tests suggest that certified pads should hold up well in a slide. The main limitation of these pads is that they cover a small surface area. Only a few common points of impact are protected.

EN 14120 isn’t widely used outside of Europe. Non-European companies may not get their pads certified, or may not mention the certification if they do. The standards don’t seem especially hard to meet, though, so my guess is that, outside of Europe, many non-certified pads from companies with good reputations will meet EN 14120 standards despite not being certified.

Hard shell body armor

EUC riders often wear body armor suits like the Leatt 5.5 Body Protector and Fox Racing Titan Sport Jacket. It seems safe to say that this armor provides more abrasion protection than skateboard pads, for the simple reason that they have more pads and the pads cover more surface area.

However, these suits don’t get tested for abrasion resistance. Since they’re intended for offroad use, they’re only tested for impact protection. That makes it difficult to say when exactly they can be suitable for the road. The amount of abrasion protection may also vary widely from one product to another.

The results of a bunch of crashes demonstrate that (at least some of) these body armor suits provide decent abrasion protection for EUC riding. Still, since they aren’t designed specifically for the road, I hesitate to recommend them. Some of these jackets may provide more protection than a good mesh motorcycle jacket. Others that are cheaply made may not protect the wearer at any speed.

Some factors to consider when deciding if an armor jacket is suitable for the road:

- How durable and abrasion resistant are the hard shells?

- Will the restraints hold the pads in place in a crash followed by a slide?

- How abrasion resistant is the lining on the parts of the jacket not covered by a hard shell?

Because plastic shells can provide high levels of abrasion resistance, I think it’s sensible to treat quality body armor jackets like a mesh street jacket. Usually these jackets are certified for urban riding, i.e. maximum speeds of around 40mph.

Motorcycle clothing

Most motorcycle clothing includes abrasion resistant materials. The current European standard for motorcycle clothing, EN 17092, tests abrasion resistance with a Darmstadt machine, which simulates sliding to a stop on pavement.

EN 17092 specifies three levels of certification: class A (meant for urban riding), AA (meant for touring), and AAA (racing). According to motorcycle gear expert Roy at mcgearhub.com, class A garments are suitable for speeds up to 40mph, and class AA up to 75mph.

These speeds are actually higher than the speeds used in the Darmstadt testing. Another consideration, though, is that the pads beneath often provide more protection after the outer suit is torn (though you are really pushing the garment to its limits at that point).

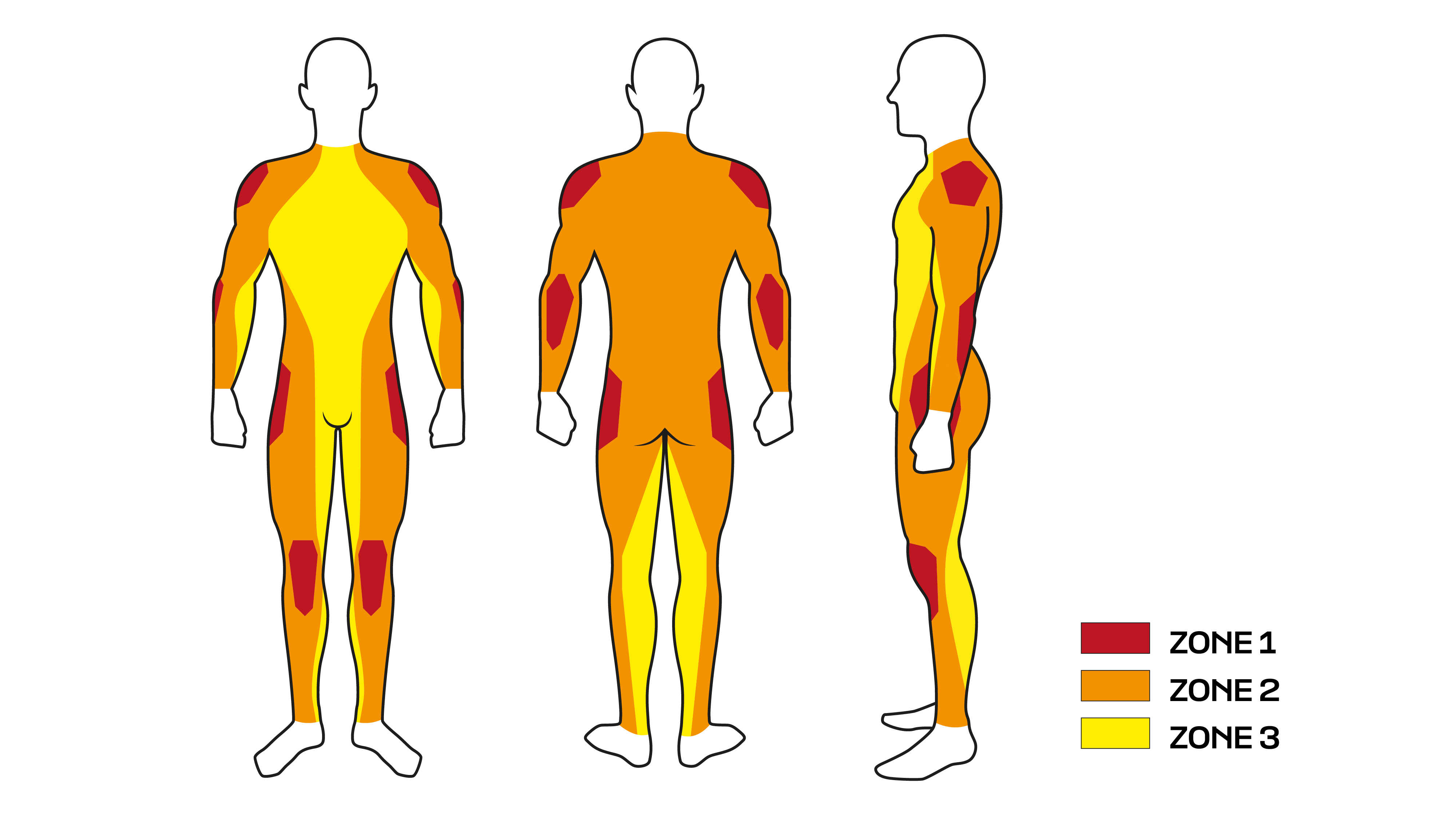

The certification splits garment areas into 3 zones depending on how much protection they require:

The table below shows the Darmstadt speeds (in kph, not mph) for the different zones. These numbers are only a rough guide to how the garment will perform in a real crash, since road conditions will usually differ from the Darmstadt test.

| Class | Zone 1 | Zone 2 | Zone 3 |

|---|---|---|---|

| A | 45 | 25 | – |

| AA | 70 | 45 | 25 |

| AAA | 120 | 75 | 45 |

Many motorcycle jackets come with loops or a zipper to attach to pants. This connection helps prevent the jacket from sliding up in a crash.

It’s surprisingly complicated to predict the abrasion resistance of a garment from its construction. As a result, I find it easier to rely on testing and certification rather than worry about the specific materials of a garment. John Milbank from BikeSocial explores some of the complications in this video:

Another source of information is the Australian testing group MotoCAP. Their standards are high, and you should expect the kind of urban riding gear that’s relevant to most EUC riding to achieve something like 2 out of 5 stars on their scale.

The Institute for Frontier Materials published an in-depth review document, A guide to designing and manufacturing motorcycle protective clothing, for those who want to know more details.